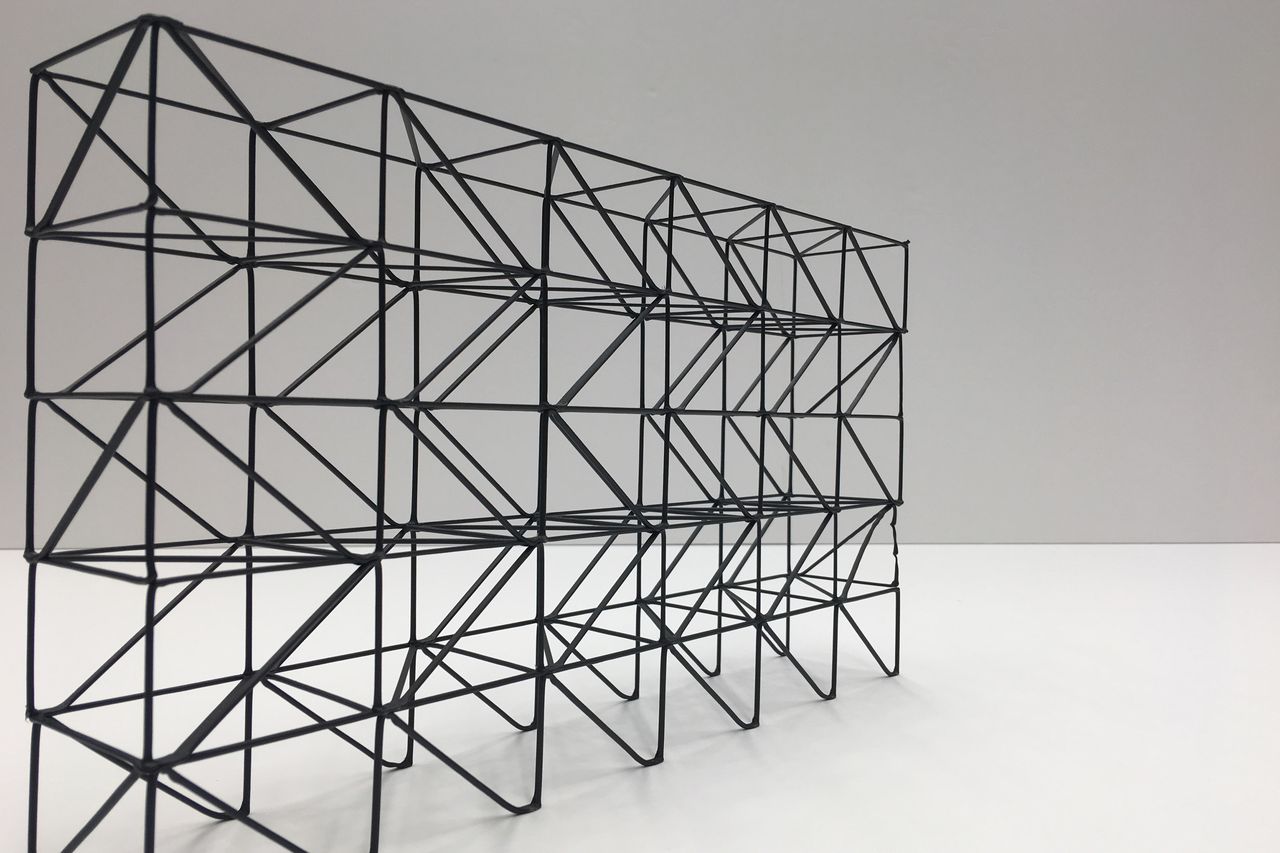

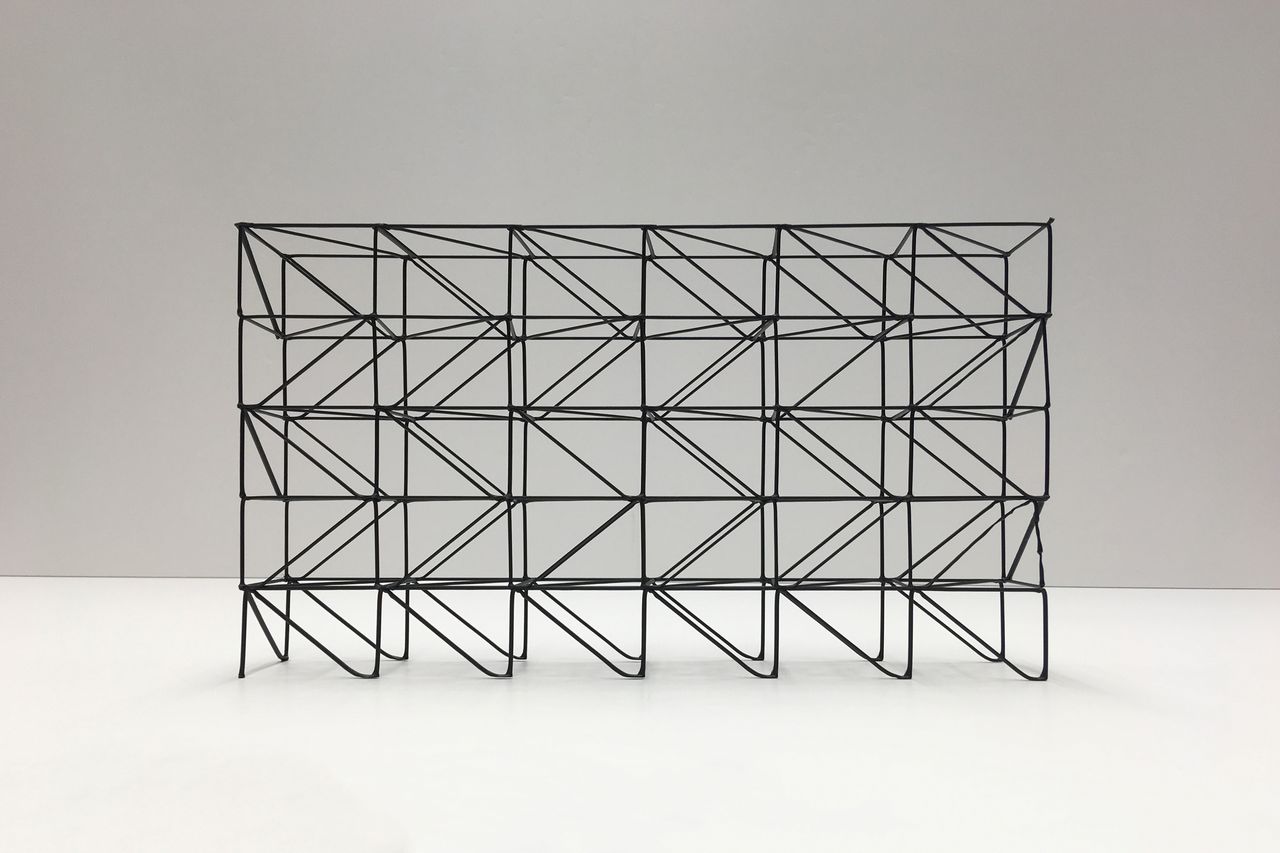

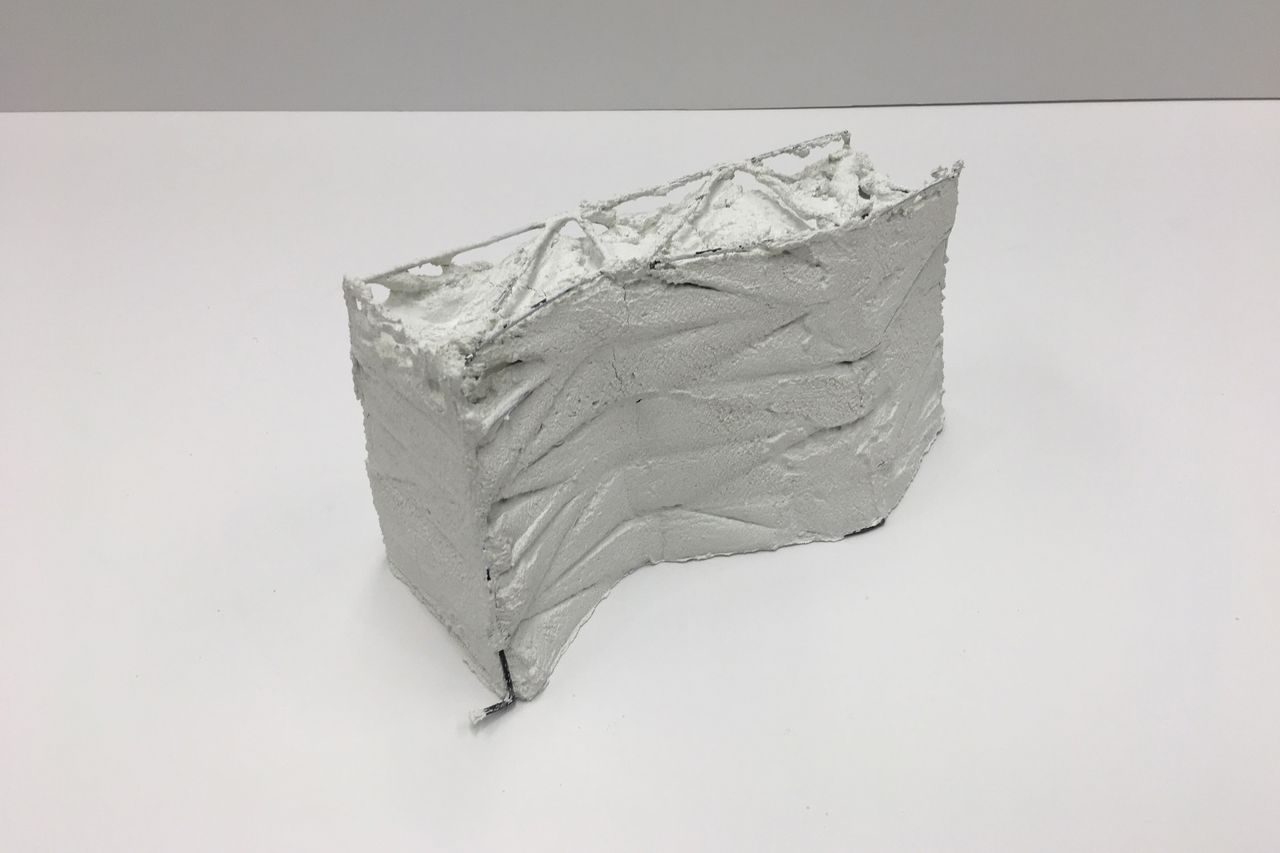

Spatial Printing

Mesh Mold CastingSpatial Printing from Yi-Liang Ko on Vimeo.

Spatial Printing aims to investigate parameters of the extrusion process through KUKA 7-Axis Robot. This extremely delicate process is involved in many factors. Besides comprehend the basis of operating robots, designers should be aware of material properties and the deviation between computational design and physical fabrication. There are three main areas would affect the result. The first one is geometry design. The final shape is a compromise between the tool end size and the carbon fiber properties. Another is toolpath. To keep the extrusion process smoothly, a continuous toolpath is generated through reorganizing points data and assign overlapping range. In addition to the factors mentioned above, the final one is end-effector. Through adjusting velocity and temperature, all parameters should correspond to geometry and toolpath. After printing, the mesh mold could catch the concrete without any formwork directly.

year: Fall 2018

type: Digital Fabrication / Material Research

course: Robotic Engagement, Taubman College

partner: Hong-Fen Lo

advisor: Wes McGee

status: Completed

size: 36cm X 6cm X 20cm ; 24cm X 10cm X 12cm

location: Ann Arbor, MI