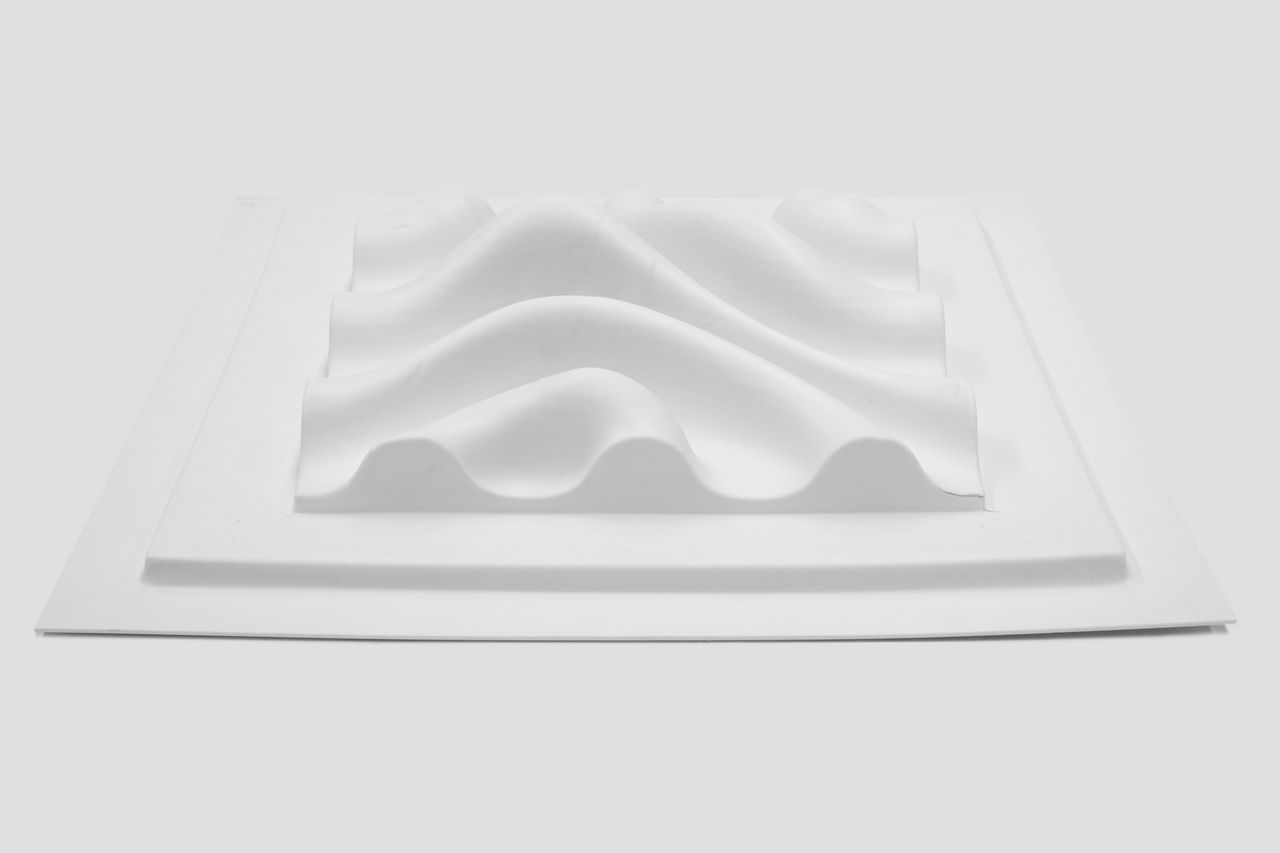

3D Tiling

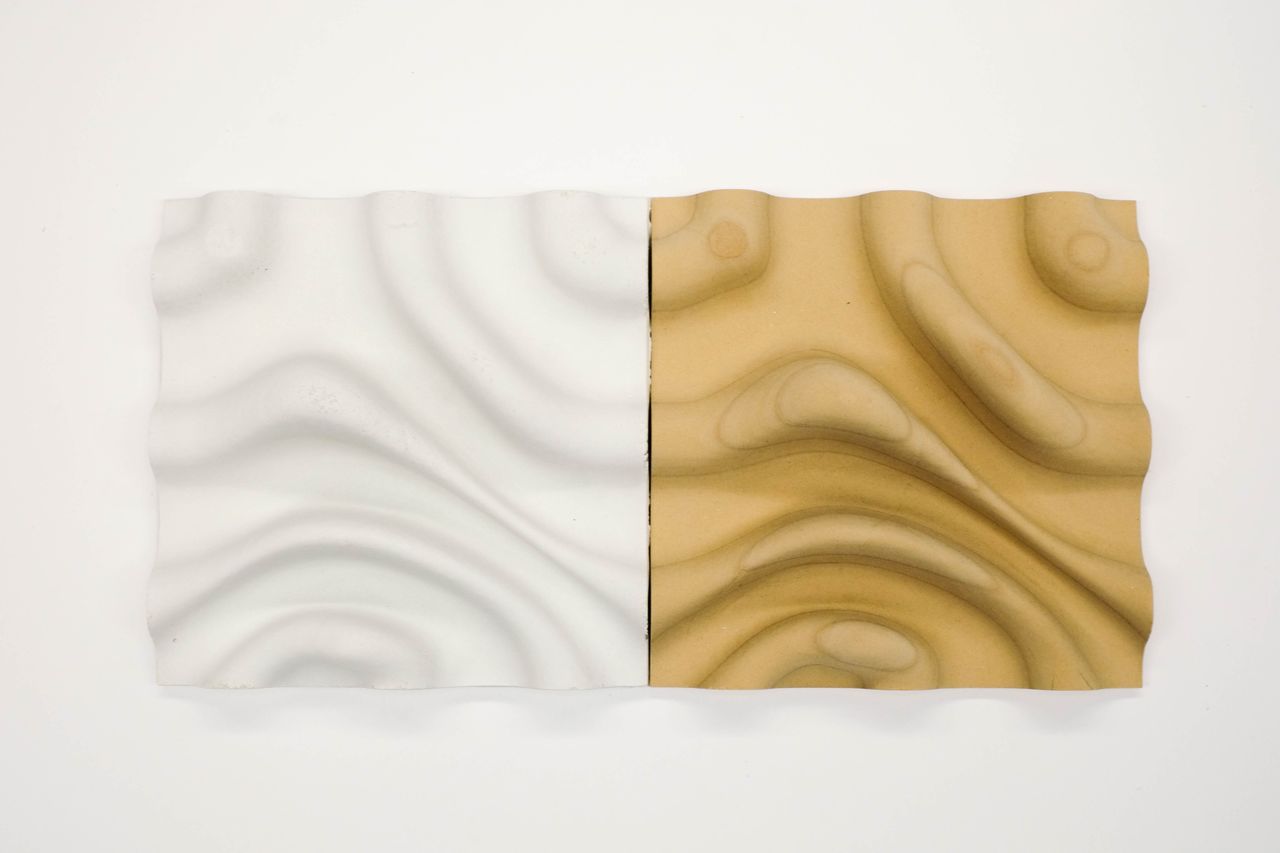

Polystyrene Vacuum Forming

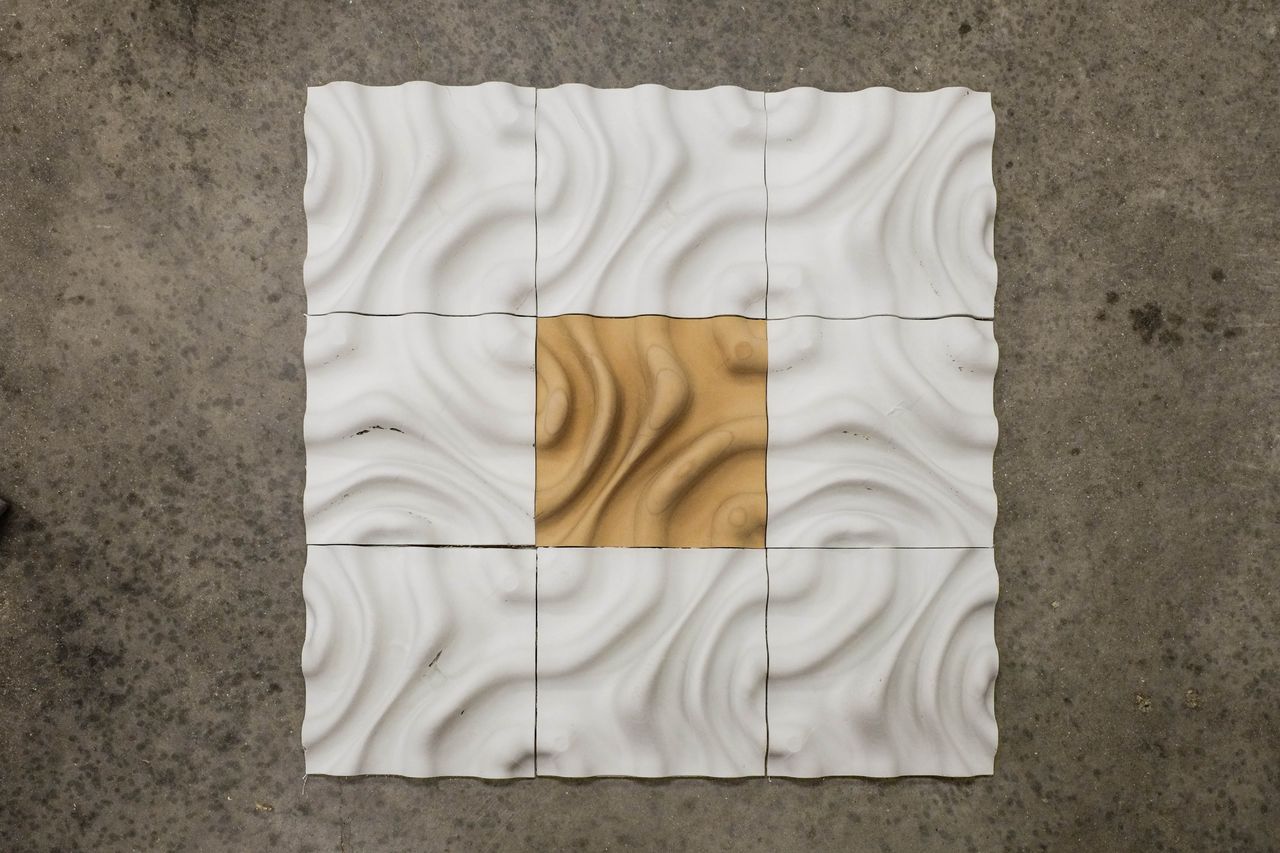

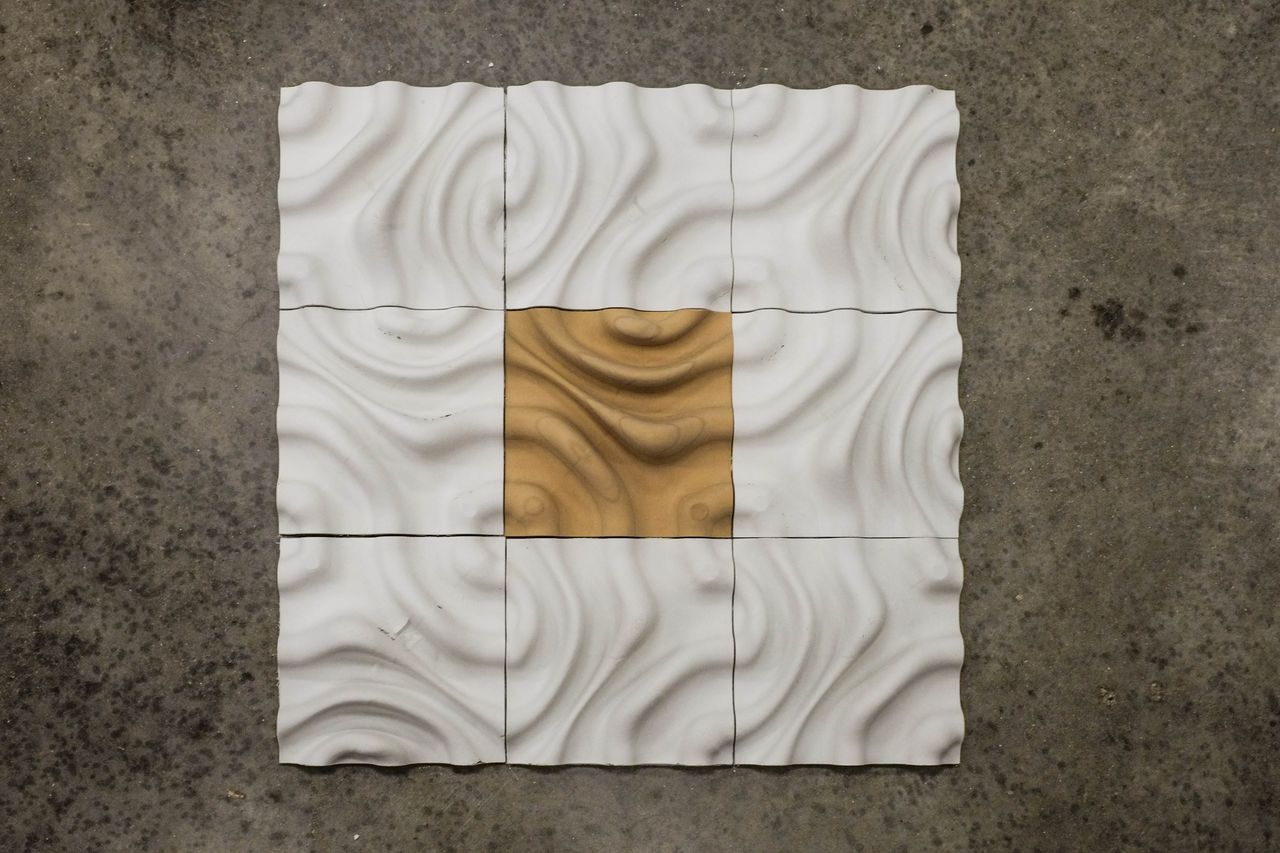

3D Tiling aims to develop a 3D tile or series of tiles that

aggregate to create a complete 3D surface. How to create a complicated surface

through an efficient way is the goal of this project. To achieve multiple

patterns and maximize efficiency, we created an identical unit which could be arranged

in four different directions. Through combining CNC Router and vacuum machine,

we contrived a workflow of production unit molds. Because the unit is

identical, we only need one CNC-milled positive MDF unit. With vacuum machine,

we could get vacuum-formed molds as many as we can. Through arranging in a

different orientation, we could achieve 16 different continuous patterns

between two units. Additionally, a lightweight unit could be achieved by

integrating Glass Fiber Reinforced Concrete (GFRC). Therefore, this module

system provides not only an efficient production process but also a practical

assembly methodology.

year: Fall 2018

type: Digital Fabrication / Material Research

course: Material Engagement, Taubman College

partner: Shan-Chun Wen

advisor: Glenn Wilcox

status: Completed

size: 12” X 12” X 3”

location: Ann Arbor, MI