AR Bending Shell

a Practice of Augmented Reality Building Process

Augmented

Reality does not only describe a method where the environment is perceivable

and is overlaid with 3D information but also allows to demonstrate complex

information on site. With advanced technology, architects can convey digital

information to a construction crew. AR Bending Shell utilizes hologram imaging

as a guide for the fabrication process of a bending-active linear shell. The

Hololens is used as a means to promote a rapid and efficient technique of

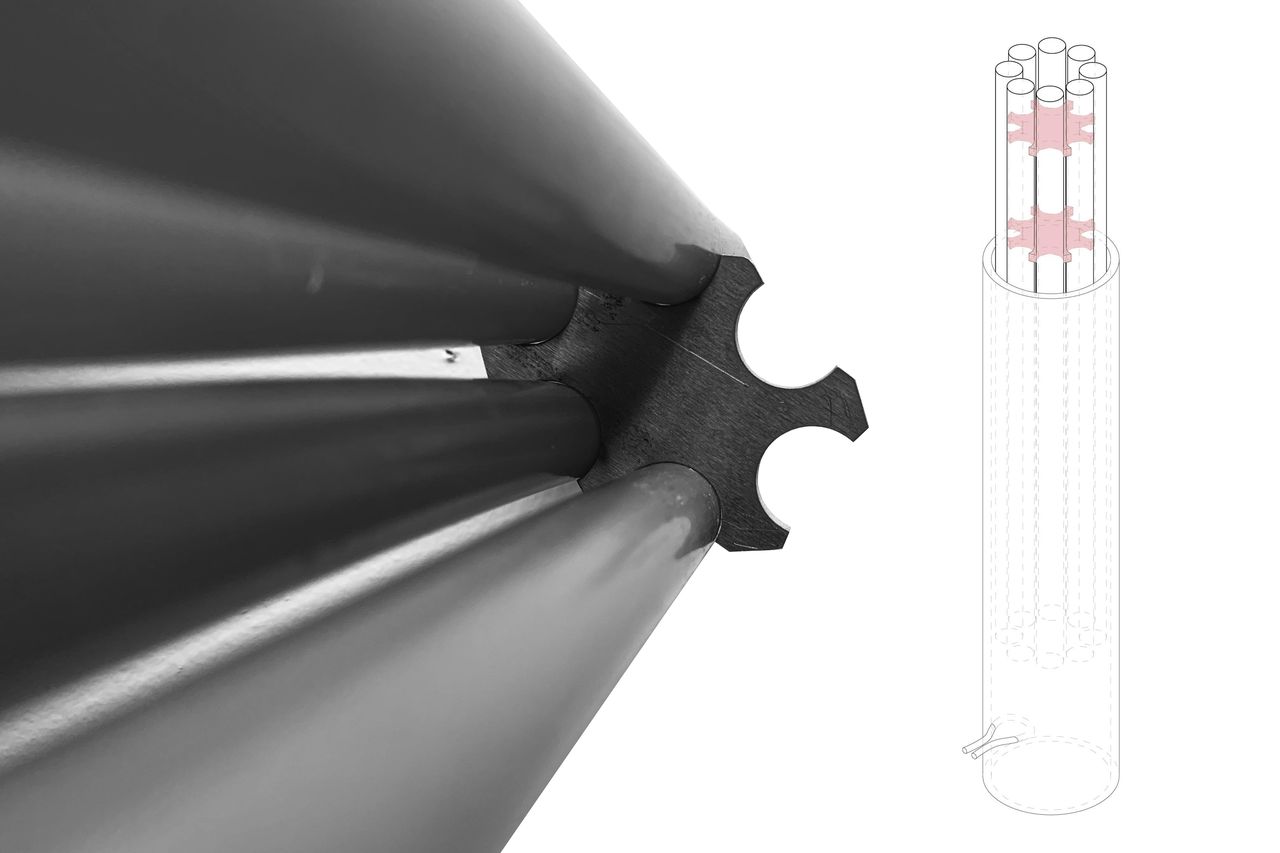

assembly, one that eliminates custom jigs and fixtures. In this project, the

computational generation of form is directly driven and informed by physical

behavior and material characteristics. Therefore, the virtual guide is

necessary due to the complexity of the design pattern and the nature of the

material (PEX pipe).

There

are three steps to build a pavilion through the AR method. Based on the

material properties, the material-oriented digital model indicates information

such as lengths, curvatures, and patterns of components first. Subsequently, the projected 3D design viewed

through the Hololens eases the fabrication process and creates a seamless

workflow between digital design and physical assemblies, such as real-time 3D

simulation of the bending structure, alignment, and positioning of the

individual elements, as well as real-time curvature measurements without the

use of customized tools. Finally,

locating 3D positions on site and erecting the flat pattern made of pipes.

Through AR device, the physical model could be adjusted in real-time. This

project demonstrates a practice of AR building process.

year: Fall 2018

type: Digital Fabrication course: Virtual Engagement, Taubman College

partner: Maryam AlJomairi, Apoorva Jalindre, Hong-Fen Lo, Shan-Chun Wen

advisor: Matias del Campo

status: Completed

size: 142” X 142” X 82.5”

location: Ann Arbor, MI