Metal Interlace

Zero-Welding AssemblyMetal Interlace from Yi-Liang Ko on Vimeo.

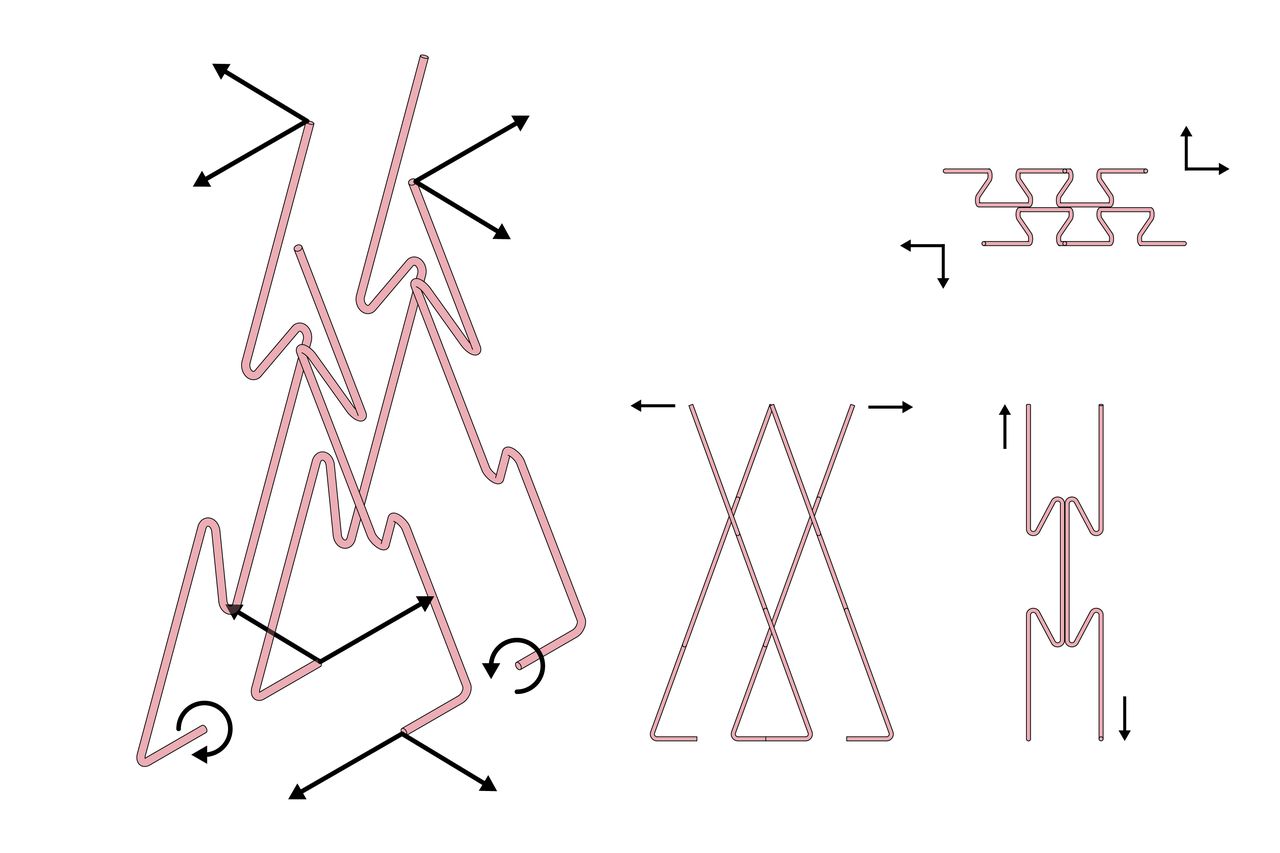

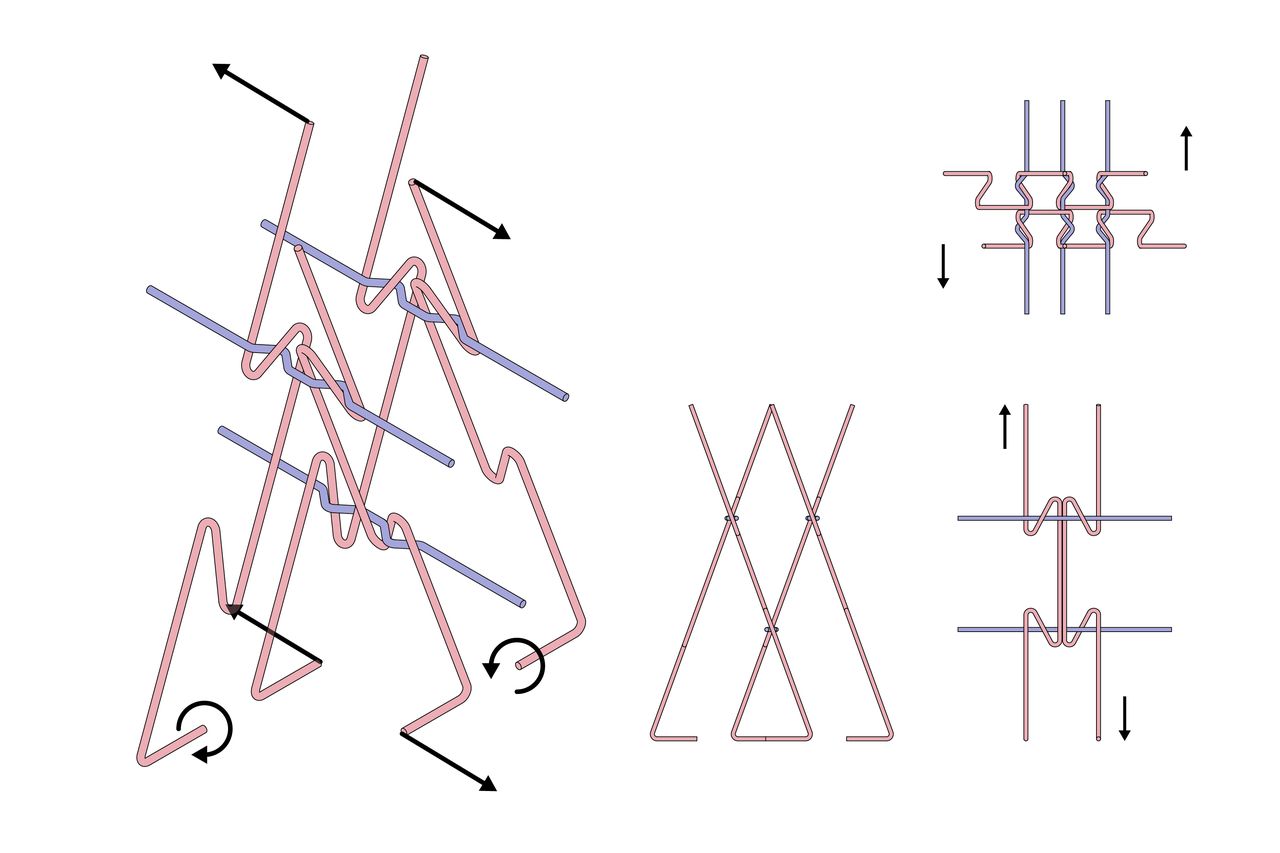

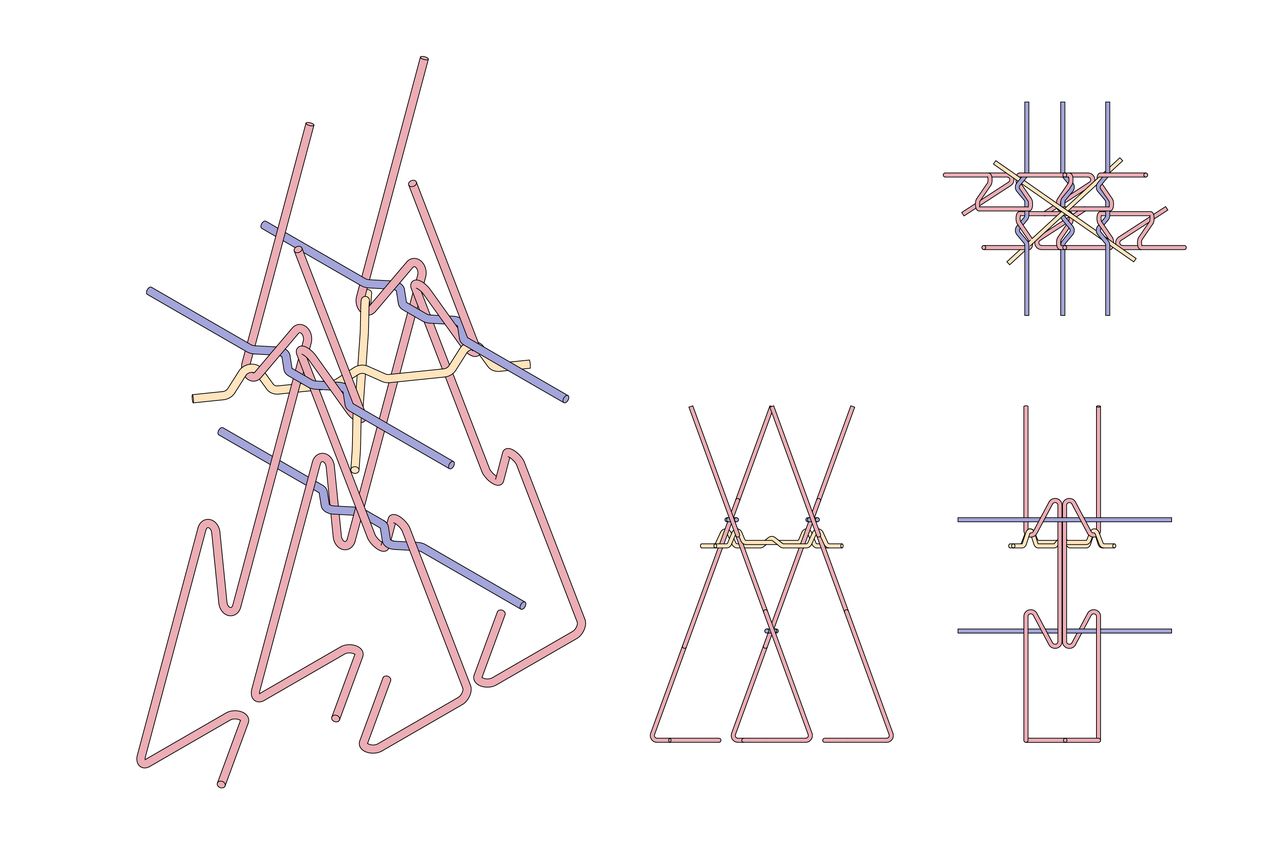

The

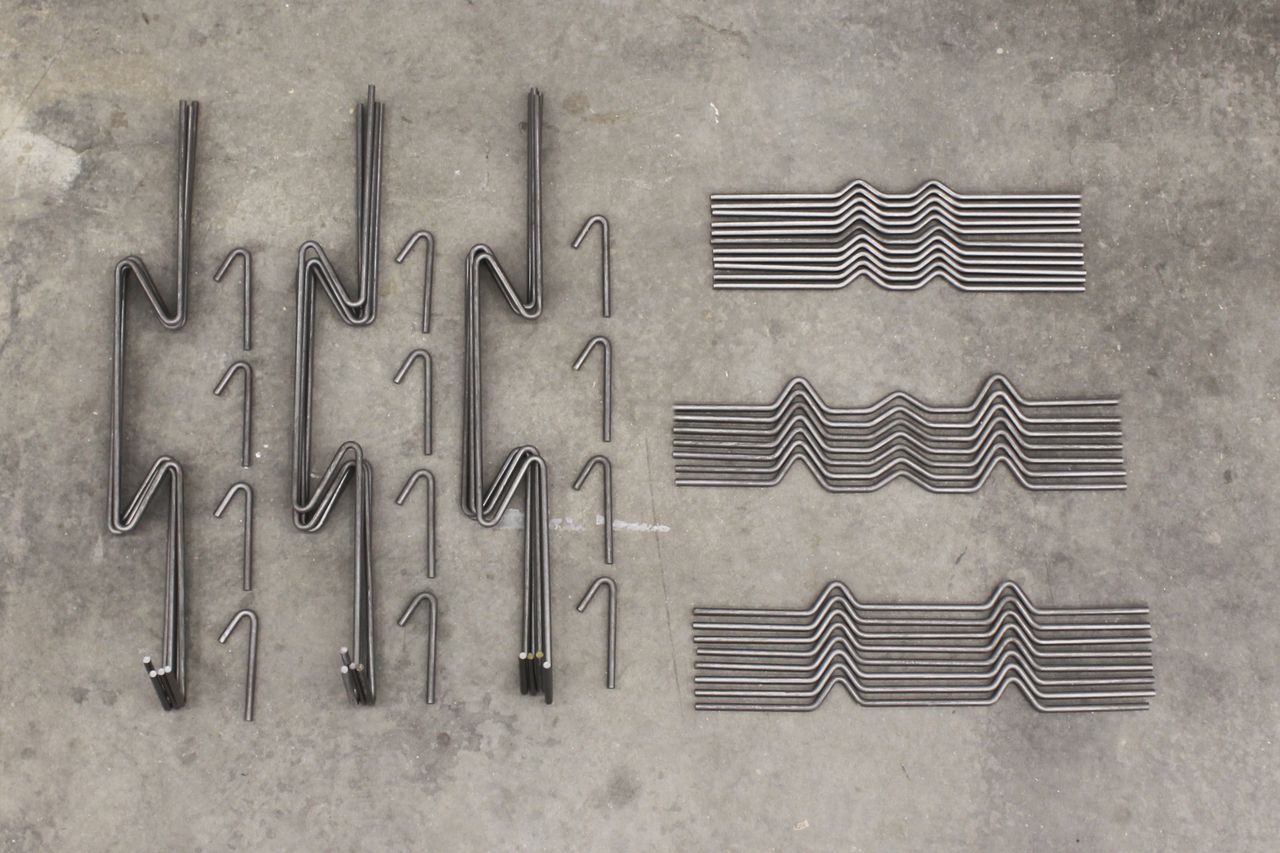

robotic rod bending process developed at the Taubman College allows a generic

industrial robot to cut and bend steel rods into specific length shapes. Based

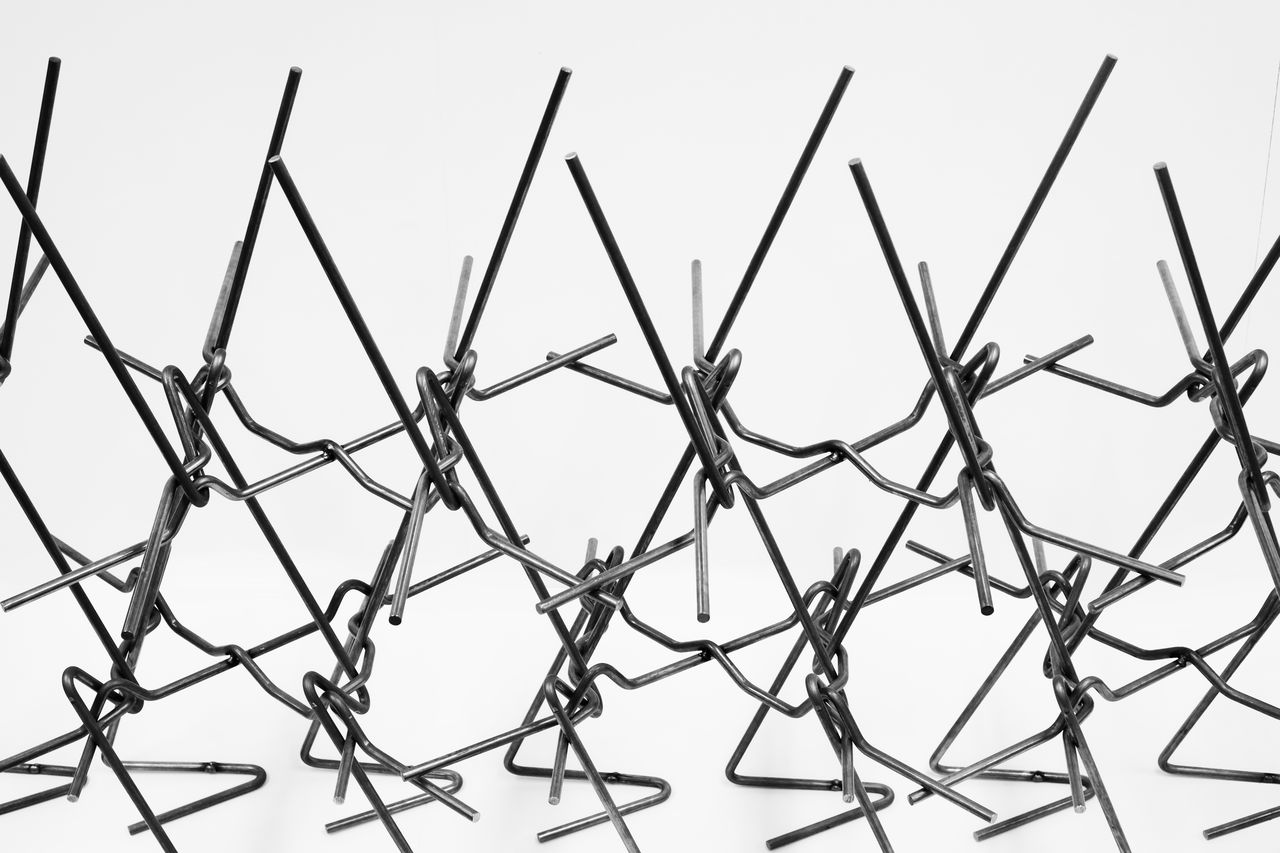

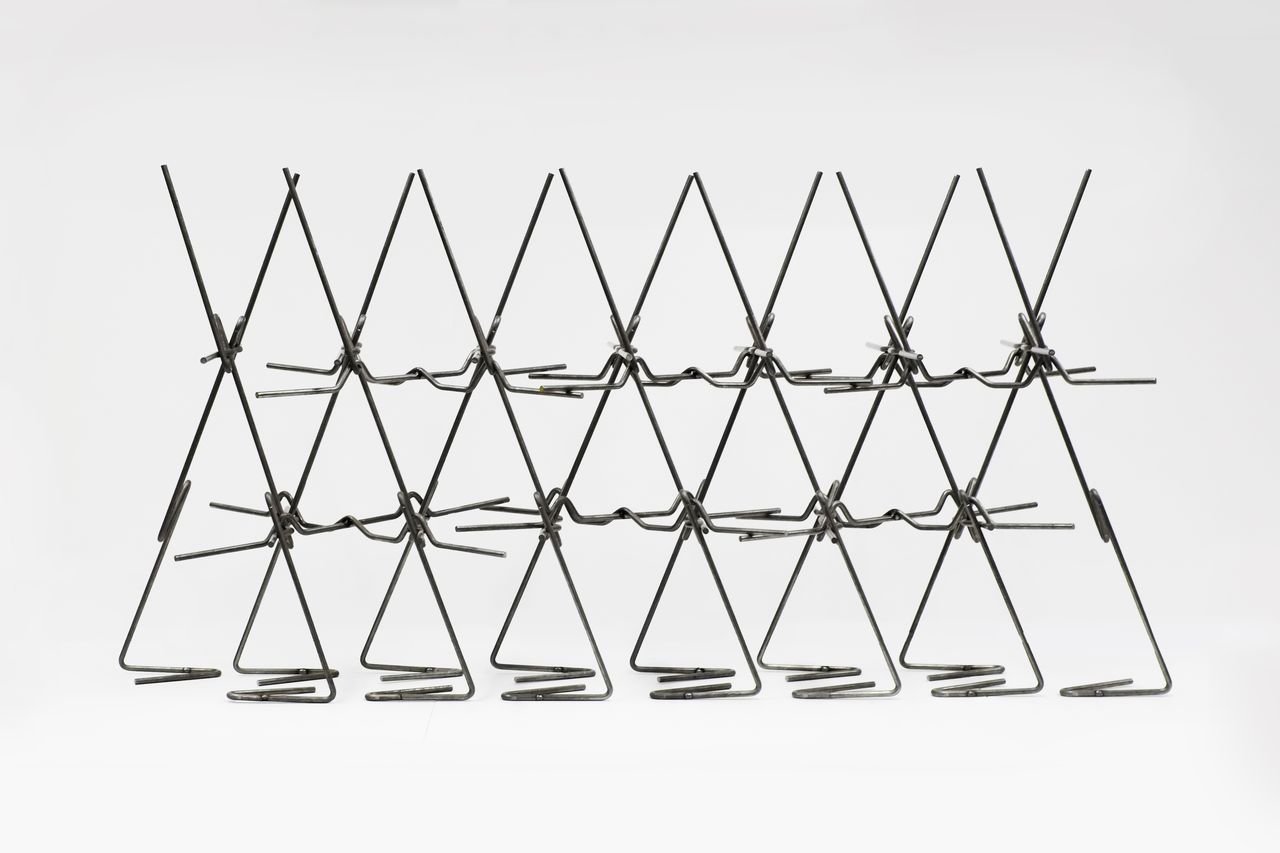

on the tools above, Metal Interlace aims to develop an aggregation system

without welding. Through exploring different lengths, curvatures, and angles,

we create 3 types of 2D units and a specific assembly order to form 3D

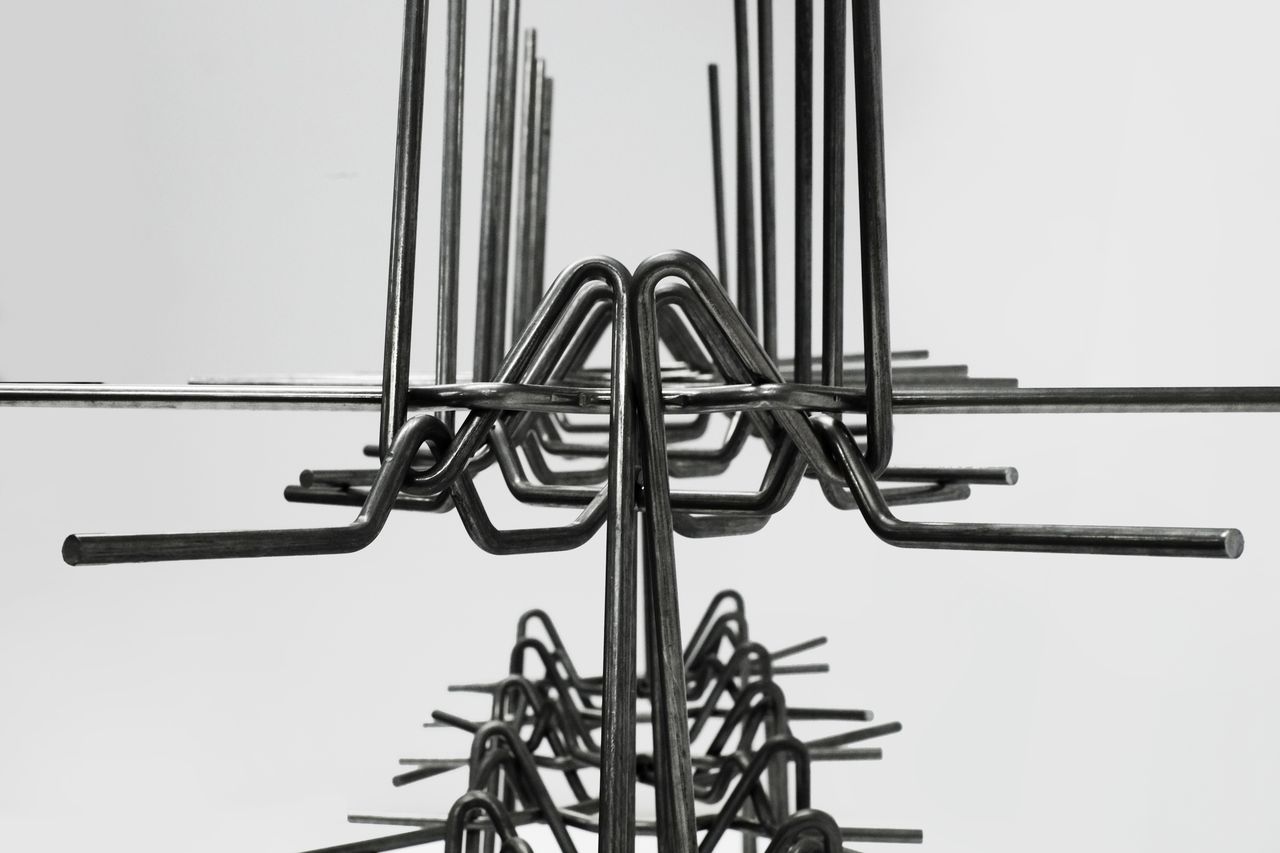

geometry. The main idea is utilizing hook systems to connect different units

together by a series of actions such as sliding, rotating, and folding. The

limitation of rod bender’s

folding angle and 7-Axis Robot’s

grip length constrain the geometry of each rod. Therefore, this is an

experiment played between digital modeling and physical restriction back and

forth. For the final piece, we created an assembly system for a foldable and

continuous metal fence.

year: Fall 2018

type: Digital Fabrication

course: Robotic Engagement, Taubman College

partner: Maryam AlJomairi, Joon Kang

advisor: Wes McGee

status: Completed

size: 52” X 12” X 24”

location: Ann Arbor, MI